Now that you know everything about the SMD and COB LED strip comparison, hopefully, you have gathered enough information to make an informed decision about which one to choose for your project, depending on the particular necessities and end goal. It all comes down to whether detail control and effects (SMD) are more important to you or if you require seamless, high-quality backlighting (COB).

Key Differences Between SMD and COB LED Strips

Structural Variations and Their Impact on Performance

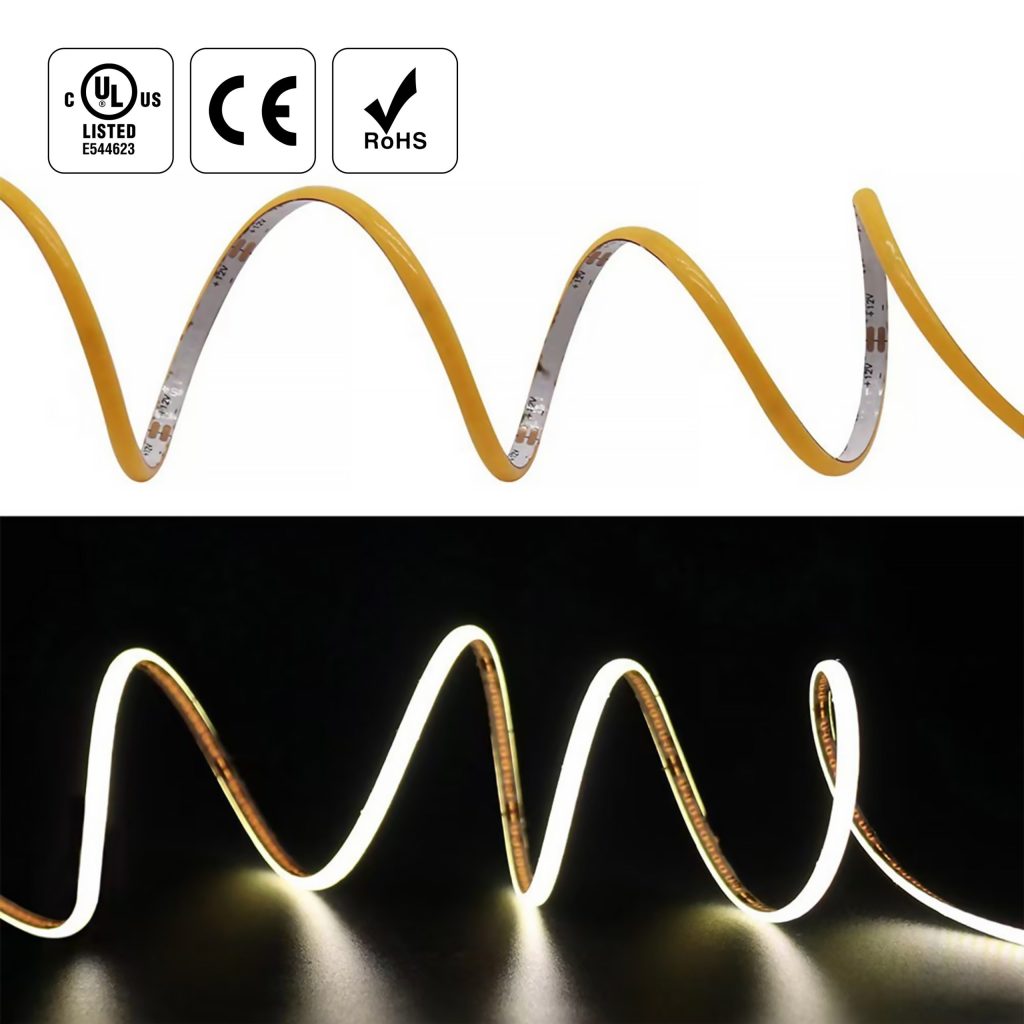

The main characteristics of Surface-Mounted Device (SMD) and Chip-On-Board (COB) LED strips are that their structure is different, and this has a direct impact on how each type operates. SMD LEDs are single diodes placed on circuit boards, and they typically come in array form. They are NOT close knit create visible dots of light. On the other hand, COB LED strips combine many LED chips closely packed onto a single substrate with no separation between them which provides a continuous and smooth line of light.

COB LEDs have a compact design and the thermal management is enhanced since the architectural design is integrated. This makes it easier for heat to dissipate than SMD LEDs, which depend on outside heat sinks or aluminum channels. This enables a more efficient heat dissipation as compared to SMD LEDs that need external heat sinks or aluminum channels.

Light Quality and Distribution Characteristics

COB LED strips are great for having an even light without the dotted effect of SMD LEDs. With an ultra-wide beam angle higher than 180°, they provide even light distribution; these LED light bars are perfect for smooth illumination applications.

In contrast, SMD LEDs have a more directional property with a narrower beam angle, which would better suit accent lighting or areas needing focused brightness. Plus, the Color Rendering Index (CRI) values of the COB LEDs are higher. This makes them ideal for settings where proper color reproduction is important.

Efficiency and Power Consumption

Both technologies are energy-efficient; however, COB LED strips typically outperform SMD variants in luminous efficacy due to their concentrated chip arrangement. They provide more lumens per watt while consuming less power.

While SMDs are still very efficient, they often demand higher power than COB to produce the same brightness. This is one of the main reasons why COB strips are widely used for projects that need to save energy without sacrificing lumens.

Application Scenarios for SMD and COB LED Strips

Optimal Uses of SMD LED Strips in Projects

SMD LED strips are very flexible and hence have a wide range of applications, and they are available in different colors and intensity ranges. They are perfect for decorative ideas, holiday decorations, or indoor accents.

SMD LEDs produce adequate brightness levels for commercial use cases like display cabinets and signage and are available in a variety of colors with controllers and/or dimmers for adjustment. This characteristic makes them cost-effective in large-scale installations.

Ideal Situations for Using COB LED Strips

With minimal visual distractions, COB LED strips excel in situations that require excellent lighting quality. Ideal for linear applications such as those in architectural lighting projects such as hotel lobbies or linear display applications, their output characteristics are extremely uniform light.

They also work well in task lighting applications, such as for workstations that require glare-free light. Outdoor projects also benefit from COB technology due to its durability and resistance to environmental factors when paired with waterproofing solutions.

Durability and Lifespan Considerations

Heat Dissipation Mechanisms in SMD vs. COB LED Strips

Either way, heat management is considered the key to longevity for both types of LED strips. COB LEDs, with a compact design that allows for multiple chips to be placed on a single substrate, have less need for external measures to support their thermal management system, whereas SMD LEDs require external heat sinks or aluminum profiles to effectively dissipate heat.

The use of a thermal pad also reduces thermal resistance and provides stable operation even in case of prolonged use. Even higher-end products utilize advanced materials like ceramic substrates that make the COB product’s thermal performance efficient enough to work in challenging environments like industrial lighting applications.

Maintenance Requirements

Additionally, due to their durable structure and good heat dissipation method, COB LED strips do not require much maintenance. Seamless design virtually eliminates the possibility of dust from being lodged between chips — a major problem with SMD LEDs that can impair light output and performance as time goes by.

By contrast, SMD LED constructs tend to require some cleaning. Nonetheless, both technologies enjoy benefits from add-ons like mounting clips and protective channels that make the tech more durable and more user-friendly to install.

Factors to Consider When Making a Choice

Budget Constraints and Project Scale

Your first consideration when weighing SMD vs. COB LED strips is the size of your project and your budget. Because of the cheapness and flexibility of SMD LED strips, these are usually more economical for big installations.

On the other hand, even if COB LED strips may seem expensive upfront, it is a good solution when looking for quality light while minimizing service, which is sometimes necessary with low-quality standard strips.

Desired Aesthetic and Functional Outcomes

Your project needs aesthetic and functional considerations that have a large effect on whether you should utilize SMD or COB-based LED technologies. If your project needs to ensure uniformity of light distribution without visible dots COB is the best possible choice.

Conversely, SMD LED strips shine when it comes to focused light or colorful effects. With their narrower beam angle, they work well for accent lighting in a venue or home.

Integration with Raymates Products

Recommended SMD LED Strips from Raymates

If versatility and cost-efficiency are high on the list, you cannot go wrong with SMD LED strips. Individually engineered, these strips present anything from RGB set-ups for full flair decorative, to single-color for only specific lighting endeavors.

Flexible PCB design ensures easy installation on different surfaces which makes them suitable for both residential and commercial applications.

Raymates COB LED Strip Options for Professional Applications

For professional-grade projects requiring seamless light output and superior durability, Raymates’ COB LED strips offer unparalleled performance. These products feature advanced thermal management systems with certificates that enhance longevity while maintaining consistent brightness levels.

One of the most notable uses for these COB strips is with architectural lighting. As an example, these have been used to great effect in hotel lobbies to provide warm but still posh vibes. The waterproof versions broaden their applicable environments to outdoor locales like the peripheries of bridges or the landscapes of parks.

Opting for the innovative solutions offered by Raymates means you have personalized support that is customized to your needs. With everything from project consultations to step-by-step installation guides, their full-service offering provides a smooth journey from the beginning to the end of the process.

FAQs

Q1: How do you choose the best suitable SMD or COB LED strip for your project?

A: Think about what your project needs—SMD LEDs are best for decorative solutions with dynamic elements and COB LEDs are ideal for uniform light output for professional applications.

Q2: Are Raymates’ products compatible with different power systems?

A: Yes. Raymates offers products compatible with both low-voltage (e.g., 12V/24V) and high-voltage (e.g., 110V/220V) systems.

Q3: What accessories are recommended when installing COB LED strips?

A: Accessories such as aluminum channels for heat dissipation and mounting clips ensure secure installation while enhancing the overall performance of the LED strips.